Surgical Camera & Instruments Manual Extraction

The risk of certain failure modes always exists in the medical device industry while patient safety remains paramount. I was able to lead this project which required implementing a manual override to ensure quick release of a patient in the case of an emergency.

Background and Introduction

Vicarious Surgical's camera system grants surgeons 360 degree visualization of a patient's abdominal cavity. This is accomplished through the use of a pair of high FOV image sensors mounted within a mechanical assembly capable of being robotically manipulated in space.

The camera's control housing, located outside of the patient, interfaces with motors in the capital equipment. This control housing contains a series of cable spools which, when rotated, are able to drive the camera in roll, yaw and pitch motion.

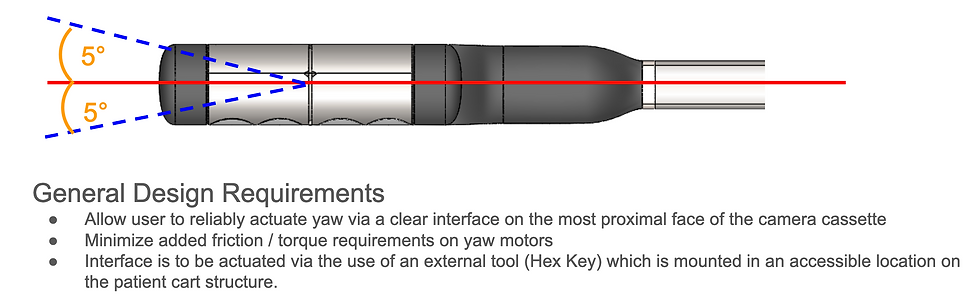

Certain failure modes such as a loss of power, loss of imaging, electrical or

Mechanical malfunction, or a clinical emergency necessitate the implementation of a manual user interface. This interface should be able to be easily accessed during a procedure and be capable of driving the camera into an extractable pose.

Design and Development

I was able to lead this project, starting from nothing but a small set of requirements into a fully implemented mechanism that was able to apply to both camera and instruments control housings.

Through numerous prototype designs, adaptations to updated control housing geometries and small run assembly implementations, the mechanism was optimized to achieve desired results with minimum added complexity

Reducing the number of added parts, their cost, and added manufacturing difficulty was paramount considering the disposable nature of the entire camera assembly.

Testing & Evaluation

After each prototype assembly was put together, a number of tests were run to evaluate the design on both a bench-top and full system scale. Metrics included performance, human factors / ergonomic quality, added weight, added drive friction, etc.

Emphasis was placed on speed of actuation. Clinical emergency cases required that the camera be moved to an extractable pose within less than a minute. Any delays were unacceptable and could lead to dangerous operating conditions.

Figure 4 above demonstrates a benchtop test setup consisting of a carriage mounted on a linear rail system. The white structure mounted a control housing in place while the carriage allowed the camera to be plunged into a system trocar. Once within the trocar, the camera would be randomly moved to an unextractable postion. The tester would then activate the manual extraction interface and evaluate the ability of the camera to be easily removed from the simulated patient.

Current Project State

The manual extraction mechanism was most recently evaluated in a full-scale formative study. This study saw a number of certified clinical OR technicians being introduced the mechanism along with a number of other system processes and mechanisms. At certain points during the study, the technician was asked to actuate manual extraction and comment on the design.

The mechanism was well-received by technicians and received praise from some. Users like the ease of access along with its straightforward nature in that it was clear how to use the interface and whether or the actuation had been successful

Manual extraction is currently being built into our largest development run of over 100+ camera assemblies. I am looking forward to any further learnings that there may be

Conclusion

I am extremely happy with the result of this project and its current state. From sketching up ideas on whiteboards and 3d printing numerous test parts and assemblies, it was not always clear what the end result would be.

I gained experience in designs using gears and best practices for their use, how to properly evaluate different ideas and down-select before going to the CAD phase, and how to collaborate cross-functionally on a project with stakeholders from 3+ departments.

This has certainly been my favorite project up to this point. The freedom to innovate early on gave me something to look forward to every day, and the success of the final design was a great way to finish up this task.